About Sankey Controls Pvt. Ltd.

Technical Expertise, Quality & Service When & Where you need it……

Sankey Controls (Formerly known as Siddharth Engineers) was established in 1999, as preferred supplier of custom-made ball valves for main Indian manufacturers. In a few years, Sankey Controls was able to earn a reputation for excellence in valve manufacturing and capacity to meet the most complex technical requirements of our clients, providing tailored made products and offering the best reliability in the application for which the valves are intended.

We specialize in designing and manufacturing a wide range of customized high performance ball valves, manually operated, automated ON-OFF or actuated and for any kind of fluid used in the Oil, Gas, Water, Steam, Petrochemical and Power Generating Industry.

Within our own facility, we are currently capable of designing, assembling and testing valves up to 16” size with pressure ratings of ANSI 150 to 2500, in accordance with almost all the recognized standards and Customer specifications. Sankey range of production includes the use of such unique materials as Super Duplex, Duplex, 6Mo, Monel, Inconel and many other alloys.

Our headquarters and manufacturing unit are based in Pune (Maharashtra, India) for a total area of 20.000sqft, the proximity to Pune International Airport – 20 Km away from our facilities, guarantees our International Customers and Partners a perfect link and easy access to our offices.

We are committed to pursuing a policy aimed at putting the Customer at the heart of the activities, by offering and adapting all processes to their needs and requirements.

The company has a Quality Management System outlined in accordance with the requirements of ISO 9001:2008 and is accredited to Pressure Equipment Directive 97/23/CE (PED).

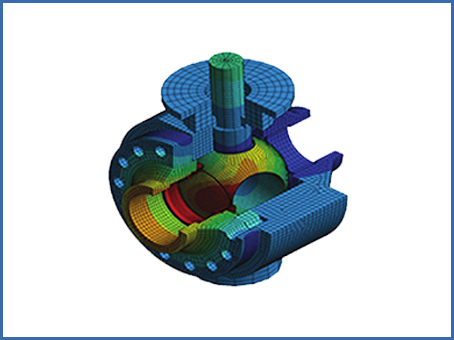

Design & Development

Technical expertise, design and experience in producing ball valves are our strong assets, thanks to a highly-experienced team of valve engineers, a professional approach to the technical aspects of valve designing and a deep knowledge of the most advanced 3D software on the market.

Production & Quality

In house fabrication for maximum flexibility The complete production process is carried out in-house, monitored and controlled. Constant investment in our manufacturing processes and machinery ensure a high level of quality, delivery and customer satisfaction. Total quality check before delivery including documentation and serial numbers for traceability

Production processes include:

Turning » Milling » Drilling » Welding » Sawing » Polishing & Grinding

Turnkey Projects, Repair and Refurbishing

To reduce the life cycle costs, it is possible to repair and overhaul the worn-out parts in our Repair department. Also, valves of other manufacturers can be repaired and overhauled. We undertake completer projects, which involves supply of valves, pressure vessels, regulators, pumps other hardware, piping instrumentation, PLC and control, data acquisition, installation and commissioning. We are approved vendor to various defense and government organizations, and have successful completed and executed prestigious project such as

- Scramjet Combustor Test facility

- Ramjet Combustor Test facility