We are Manufacturer, Supplier, Exporter of 3 Piece Flanged T-Port Floating Ball Valves, Flanged Floating Ball Valves, Floating Ball Valves. Our setup is situated in Pune, Maharashtra, India.

- Full Bore body, avoids clogging and ensures smooth flow when handling slurries and solid.

- Design in compliance with ASME B16.34 / BS5351.

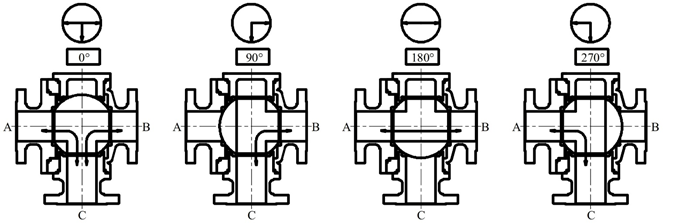

- Flow plans for T ports can be field rearranged to meet many other flow plans

- Body cavity fillers available

- Material compliance with NACE specification.

- Blowout proof stem

- Low emission packing

- 2-3-piece design for easy maintainability

- Cavity filler available.

Leakage Test:

- Class VI

Actuator mounting flange:

- DIN/ISO 5211

T-Port Design Configuration:

| TYPE : | Single Piece Wafer Type |

| PORT : | Full Bore |

| SIZE : | 15 mm to 100mm NB |

| Pressure Rating : | ASME #150 PN 20

ASME #300 PN 50

ASME #600 PN 100

|

| Temperature Range | 35 Deg C to 280 Deg C (Soft Seated) |

| Body Materials | Stainless Steel / Carbon Steel / Alloys |

| Design Standard | API 6D rev 23; ISO 17292 rev 2004 |

| End Flanges | ASME B16.5 2013 |

| Face to Face Dimension | As per manufacturer Std |

| Fire safe design | API-607 Rev 2010 |

| Testing | API 598 Rev 2009 |

| Sour Service | NACE MOR 0175 Rev 2009 |

| Documents | BS/EN 10204-3.1 REV 2004 |

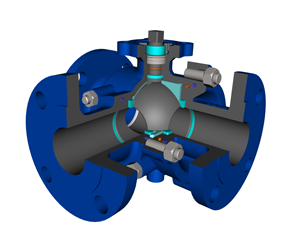

TWO - THREE PIECE, FULL BORE BALL VALVE, FLANGED END

T-Port Configuration

Sankey side entry 3-Way ball valve offers diverting and mixing/selection flow patterns and often eliminates the need for two valves. The T-port configuration is available as a 2 piece or 3 piece design in two seat and four seat configuration thus is extremely versatile in various configurations and the full port design is easily automated as it comes in and is available with various seat materials for various pressure and temperature range.

Areas of application: Chemical/ Pharmaceutical/ Food /Pharmaceutical/ Petrochemical/ Energy/ Plastics/ Oil and Gas /Cement and lubrication

ADVANTAGES

The usual cavity between ball and housing in non- cavity free ball valves give cause for disturbance because residual products can crystallize, polymerize and so affect the function.

The usual cavity between ball and housing in non- cavity free ball valves give cause for disturbance because residual products can crystallize, polymerize and so affect the function.

- Clean, non- false product

- No sediments of expensive products in the ball valve housing

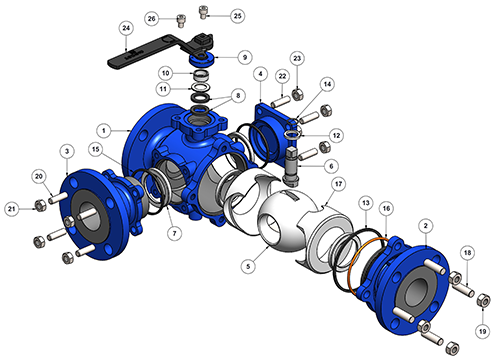

| Sr.No. | PART NAME | STAINLESS STEEL | CARBON STEEL | QTY |

|---|---|---|---|---|

| SR.NO. | PART NAME | STAINLESS STEEL | CARBON STEEL | QTY |

| 1 | BODY | ASTM A351 CF8M | ASTM A216 WCB | 1 |

| 2 | END CONN. | ASTM A351 CF8M | ASTM A216 WCB | 1 |

| 3 | END CONN. SIDE | ASTM A351 CF8M | ASTM A216 WCB | 1 |

| 4 | END CONN. BACK | ASTM A351 CF8M | ASTM A216 WCB | 1 |

| 5 | BALL | ASTM A276 SS316 | ASTM A276 SS316 | 1 |

| 6 | STEM | ASTM A479 SS316 | ASTM A479 SS316 | 1 |

| 7 | SEAT | PTFE | PTFE | 2 |

| 8 | STEM SEAL | GRAPHITE | GRAPHITE | 2 |

| 9 | GLAND | SS316 | MS | 1 |

| 10 | GLAND BEARING | DELRIN | DELRIN | 1 |

| 11 | SPACER | SS316 | SS316 | 1 |

| 12 | STEM THRUST WASHER | GFT | GFT | 1 |

| 13 | BODY SEAL | GRAPHITE | GRAPHITE | 1 |

| 14 | STEM O-RING | VITON | VITON | 1 |

| 15 | BODY SEAL | GRAPHITE | GRAPHITE | 2 |

| 16 | END CONN. O-RING | VITON | VITON | 1 |

| 17 | CAVITY | PTFE | PTFE | 2 |

| 18 | STUD | ASTM A193 GR.B8M | ASTM A193 GR.B7 | 4 |

| 19 | NUT | ASTM A194 GR.8M | ASTM A194 GR.2H | 4 |

| 20 | STUD | ASTM A193 GR.B8M | ASTM A193 GR.B7 | 4 |

| 21 | NUT | ASTM A194 GR.8M | ASTM A194 GR.2H | 4 |

| 22 | STUD | ASTM A193 GR.B8M | ASTM A193 GR.B7 | 4 |

| 23 | NUT | ASTM A194 GR.8M | ASTM A194 GR.2H | 4 |

| 24 | LEVER | SS410 | SS410 | 1 |

| 25 | ALLEN BOLT | MS | MS | 1 |

| 26 | STOPER | MS | MS | 1 |