We are Manufacturer, Supplier, Exporter of High Pressure Ball Valves, Isolation Ball Valve, Isolation Valve,. Our setup is situated in Pune, Maharashtra, India.

- full compliance to ASME B16.34

- Solid forged designed available in F304 / F316 / LF2

- Testing: in accordance to API 598

- PEEK seats

- Fire safe design with graphite seals

- Emission warranty: Maximum 100 PPM

- Port size: full and regular port

- Available with different combination ends (i.e Screwed / Tube end )

Stem Design Features:

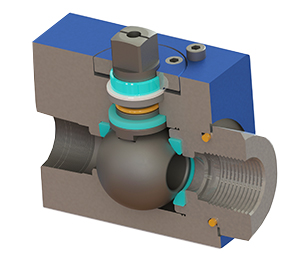

- Live loaded blowout proof stem

- Delrin thrust washer – prevents deformation under high pressure.

- Additional stem O-rings for ultra-low emission applications. *

- Antistatic- Design

Leakage Test:

- Class VI

Actuator mounting flange:

- DIN/ISO 5211

| TYPE : | Two Piece Screwed End |

| PORT : | Full & Regular (Reduced) Bore |

| SIZE : | 8 mm to 15 mm NB |

| Pressure Rating : | ASME #250 PN 420

|

| Temperature Range | 35 Deg C to 280 Deg C (Soft Seated) |

| Body Materials | Stainless Steel / Carbon Steel / Alloys |

| Design Standard | API 6D rev 23; ISO 17292 rev 2004 |

| Face to Face Dimension | As per manufacturer std |

| End Flanges | ASME B16.5 2013 |

| Butt Weld | ASME B16.25 |

| Face to Face Dimension | As per Manufacturer End |

| Testing | API 598 Rev 2009 |

| Sour Service | NACE MOR 0175 Rev 2009 |

| Documents | BS/EN 10204-3.1 REV 2004 |

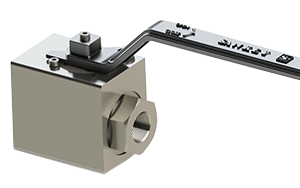

Sankey 91 series forged ball valve is a high-pressure ball valve designed for the tough and rugged standard of the of instrumentation market in a 10000-psi body configuration.

Areas of application: Chemical / Pharmaceutical / Food / Pharmaceutical / Petrochemical / Energy / Plastics / Oil and Gas / Cement and lubrication

KEY FEATURES:

- Two-piece body design - minimal leakage paths

- Pressure boundary designed safety factor

- Design complies with ASME

- Bi-directional

- Anti blowout stem

- Low torque operation

- Full hydrostatic and low pressure air tested

- Firesafe designed to meet API 607, BS6755 Pt2 (optional)

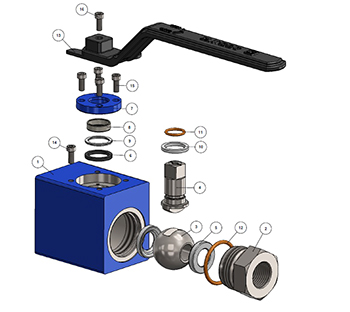

15MM FB #2500 HIGH PRESSURE VALVE

| Sr.No. | PART NAME | STAINLESS STEEL | CARBON STEEL | QTY |

|---|---|---|---|---|

| 1 | BODY MACHINING | ASTM A479 SS316 | A105 | 1 |

| 2 | END ADAPTOR | ASTM A479 SS316 | A105 | 1 |

| 3 | BALL | ASTM A276 SS316 | ASTM A276 SS316 | 1 |

| 4 | STEM | 17.4 PH | 17.4 PH | 1 |

| 5 | SEAT | PEEK | PEEK | 2 |

| 6 | STEM SEAL | GRAPHITE | GRAPHITE | 1 |

| 7 | GLAND | SS316 | SS316 | 1 |

| 8 | GLAND BEARING | DELRIN | MS | 1 |

| 9 | SPACER | SS316 | SS316 | 1 |

| 10 | THRUST WASHER | GFT | GFT | 1 |

| 11 | STEM O-RING | VITON | VITON | 1 |

| 12 | END ADAPTER O-RING | VITON | VITON | 1 |

| 13 | LEVER | SS410 | SS410 | 1 |

| 14 | STOPER | MS | MS | 1 |

| 15 | ALLEN BOLT | HIGH TENSILE | HIGH TENSILE | 4 |

| 16 | ALLEN BOLT | MS | MS | 1 |