We are Manufacturer, Supplier, Exporter of Wafer Type Ball Valves, Wafer Type Ball Valve, 1 Piece Wafer Type Floating Ball Valves. Our setup is situated in Pune, Maharashtra, India.

| TYPE : | Single Piece Wafer Type |

| PORT : | Full Bore |

| SIZE : | 15 mm to 100mm NB |

| Pressure Rating : | ASME #150 PN 20

ASME #300 PN 50

ASME #600 PN 100

|

| Temperature Range | 35 Deg C to 280 Deg C (Soft Seated) |

| Body Materials | Stainless Steel / Carbon Steel / Alloys |

| Design Standard | API 6D rev 23; ISO 17292 rev 2004 |

| End Flanges | ASME B16.5 2013 |

| Face to Face Dimension | As per manufacturer Std |

| Fire safe design | API-607 Rev 2010 |

| Testing | API 598 Rev 2009 |

| Sour Service | NACE MOR 0175 Rev 2009 |

| Documents | BS/EN 10204-3.1 REV 2004 |

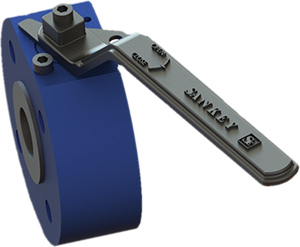

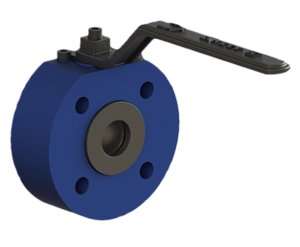

WAFER BALL VALVE

SANKEY wafer ball valves are ideally suited to applications where space is at a premium provide plus all the benefits of flanged ball valve while reducing the cost and weight. The valve can be installed between flanges with help of bolts.

Our wafer ball valve is normally one-piece design and floating ball type, and are available in both cast and forged construction in sizes ranging from DN15 to DN 100, in #150 to #900 pressure rating.

TECHNICAL DETAILS

Valve Application: Process Skids / hydraulic application / Transport vessels / Reactor.

Areas of application: Chemical/ Pharmaceutical /Petrochemical / Hydraulics

Media: Gases /Fluids /Oil / Steam / Paint /

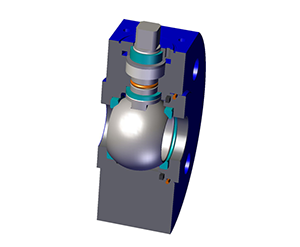

- Wafer Valve body, short face to face dimension.

- Fire safe approved (API-607)

- Cavity free (Available)

- Full bore

- Antistatic design

- Anti-blowout stem design

- Unique push fit design (easy maintainability/ low torque)

- Adjustable and maintenance free stem sealing with O-ring

Design Per Customer Requirements:

- Metal to metal sealing system for high pressure, high temperature and abrasive operating

- conditions

- Ball valve design customizable to special vessel flanges

- Extended stem

- Metal seated available (High temperature application)

Leakage Test:

- Acc. To EN 12266-1 leak rate A

Actuator mounting flange:

- DIN/ISO 5211

ADVANTAGES : SANKEY Wafer Ball Valve

The usual cavity between ball and housing in non- cavity free ball valves give cause for disturbance because residual products can crystallize, polymerize and so affect the function.

• Clean, non- false product

• No sediments of expensive products in the ball valve housing.

Push Fit Insert design

Because of the further distance from the actuator mounting flange to the vessel, it makes the automation of the ball valve and isolation of the vessel very convenient.

• Easy maintenance, quick dismantling, assembly thus fast turnaround time for the valve. • Low torque design

• Avoids unnecessary load on the seat and seals

Fire-safe tested and approved

SANKEY Wafer ball valves of the WF series have been tested successfully per British Standard BS 6755 and API-607.The material utilized for the soft seals in "fire-safe" valves remains dependent upon the required chemical resistance to suit the fluid, the application and operation conditions.

When fire does break out, it is important that it does not spread through failures in pipe-work systems.

Even under the most extreme conditions shut-off valves provide:

• Secure Operation • Reliable Sealing in shut-off position • Reliable Sealing to the outside

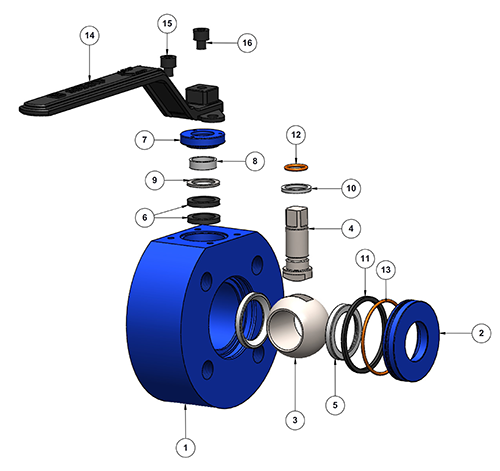

BOM

WAFER TYPE BALL VALVE

| Sr.No. | PART NAME | STAINLESS STEEL | CARBON STEEL | QTY |

|---|---|---|---|---|

| 1 | BODY | ASTM A479 SS316 | A105 | 1 |

| 2 | INSERT | ASTM A479 SS316 | A105 | 1 |

| 3 | BALL | ASTM A276 SS316 | ASTM A276 SS316 | 1 |

| 4 | STEM | ASTM A479 SS316 | ASTM A479 SS316 | 1 |

| 5 | SEAT | PTFE | PTFE | 2 |

| 6 | STEM SEAL | GRAPHITE | GRAPHITE | 2 |

| 7 | GLAND | SS316 | MS | 1 |

| 8 | GLAND BEARING | DELRIN | DELRIN | 1 |

| 9 | SPACER | SS316 | SS316 | 1 |

| 10 | STEM THRUST WASHER | GFT | GFT | 1 |

| 11 | BODY SEAL | GRAPHITE | GRAPHITE | 1 |

| 12 | STEM O-RING | VITON | VITON | 1 |

| 13 | END CONN. O-RING | VITON | VITON | 1 |

| 14 | LEVER | MS | MS | 1 |

| 15 | STOPER | MS | MS | 1 |

| 16 | ALLEN BOLT | MS | MS | 1 |