We are Manufacturer, Supplier, Exporter of Two Piece Flange End Floating Ball Valve, Floating Ball Valves. Our setup is situated in Pune, Maharashtra, India.

- Full Bore body, avoids clogging and ensures smooth flow when handling slurries and solid.

- Available fire-tested to API-607 Rev. 5

- Design in compliance with ASME B16.34 / BS5351.

- GFT thrust-washer prevents galling & prevents against deformation.

- Material compliance with NACE specification.

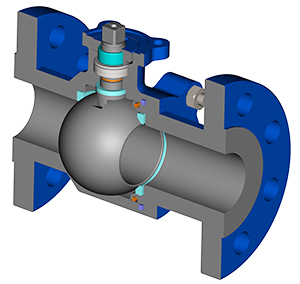

- Blowout proof stem.

- Low emission packing.

Stem Design Features:

- Full guided stem, with gland bearing

- Three layer of advance stem sealing.

- Independent stem rotation (rotation independent of gland nut)

- Extended stem available

- Double packed stuffing box design

- Antistatic- Design

Leakage Test:

- Class VI

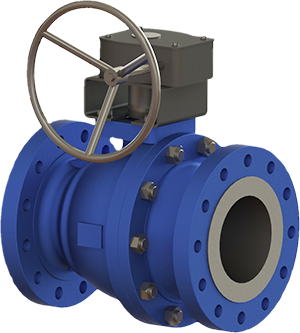

Actuator mounting flange:

- DIN/ISO 5211

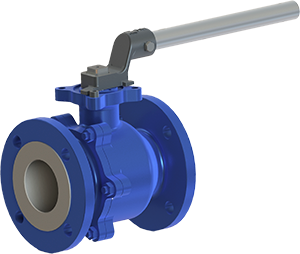

Type: Two Piece Flanged End

- Port: Full & Regular (Reduced) Bore

- Size: - 15 mm to 250mm NB

- Pressure Rating: -

ASME #150 PN 20

ASME #300 PN 50

ASME #600 PN 100 - Temperature Range: - 35 Deg C to 280 Deg C (Soft Seated)

- Body Materials: - Stainless Steel / Carbon Steel / Alloys

- Design Standard: - API 6D rev 23; ISO 17292 rev 2004

- End Flanges: - ASME B16.5 2013

- Face to Face Dimension: - ASME B16.10 Rev 2009

- Fire safe design: API-607 Rev 2010

- Testing: API 598 Rev 2009

- Sour Service: NACE MOR 0175 Rev 2009

- ocuments: BS/EN 10204-3.1 REV 2004

The Sankey series ball valve can handle a vast variety of fluids, semisolid and almost any corrosive service on chemical, oil, petrochemical, gas, pulp, paper processing and other industries. Our standard valves with CFT seats are suitable for steam up to 18 bars. These rugged, versatile and high performance ball valves can meet NACE specification. Areas of application: Chemical/ Pharmaceutical/ Food /Pharmaceutical/ Petrochemical/ Energy/ Plastics/ Oil and Gas /Cement and lubrication.

KEY FEATURES:

- 2 Piece bolted body design for ease of field service and maintenance

- Available fire-tested to API-607 Rev. 5

- Design in compliance with ASME B16.34 / BS5351.

- Extremely low torque for actuation savings.

- High Life cycle

- Inert seals suitable for most services.

- Body coated for corrosion protection.

- GFT thrust-washer prevents galling & prevents against deformation.

- Material compliance with NACE specification.

- Blowout proof stem.

- Low emission packing.

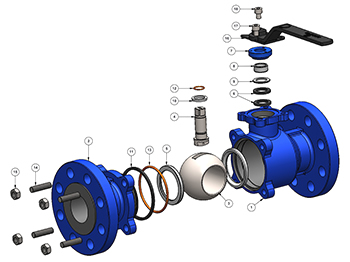

Bill Of Material

| Sr.No. | PART NAME | STAINLESS STEEL | CARBON STEEL | QTY |

|---|---|---|---|---|

| 1 | Body | ASTM A351 CF8M | ASTM A216 WCB | 1 |

| 2 | END CONN. | ASTM A351 CF8M | ASTM A216 WCB | 1 |

| 3 | BALL | ASTM A276 SS316 | ASTM A276 SS316 | 1 |

| 4 | STEM | ASTM A479 SS316 | ASTM A479 SS316 | 1 |

| 5 | SEAT | PTFE | PTFE | 2 |

| 6 | STEM SEAL | GRAPHITE | GRAPHITE | 2 |

| 7 | GLAND | SS316 | MS | 1 |

| 8 | GLAND BEARING | DELRIN | DELRIN | 1 |

| 9 | SPACER | SS316 | SS316 | 1 |

| 10 | STEM THRUST WASHER | GFT | GFT | 1 |

| 11 | BODY SEAL | GRAPHITE | GRAPHITE | 1 |

| 12 | STEM O-RING | VITON | VITON | 1 |

| 13 | END CONN. O-RING | VITON | VITON | 1 |

| 14 | STUD | ASTM A193 GR.B8 | ASTM A193 GR.B7 | 4 |

| 15 | NUT | ASTM A194 GR. 8M | ASTM A194 GR.2H | 4 |

| 16 | LEVER | ASTM A216 WCB | ASTM A216 WCB | 1 |

| 17 | STOPER | MS | MS | 1 |

| 18 | ALLEN BOLT | MS | MS | 1 |